Parquet

Herringbone, Hungarian Point, Basket Weave & more…

Bring a touch of nature into your home with parquet.

Every home will have a different feel and atmosphere depending on the shape, size, furnishings and people living there. There are hundreds of variations of parquet including pattern, colour, finish e.g. aged, smoked, classic etc providing options for every home. A parquet floor is also a long term investment and we fully understand that choosing the right floor can be a tough process. We are very happy to help and will do all we can to make this choice easier for you.

The 3 favourites most commonly installed

Parquet was first known to have been introduced in the 16th Century and came about as a replacement for the marble floors used due to being easier to clean and maintain. The trend for parquet continued well into the 18th C. with flooring patterns becoming more elaborate and ambitious. It was an opportunity wealthy homeowners used to portray wealth.

Today flooring gives designers and architects the opportunity to, with the help of modern machinery, experiment with even more intricate designs and integrate new woods, materials and finishings.

‘Your floor is a piece of art.’

The herringbone has maintained its number 1 spot on the favourites list followed by the Hungarian point. They’re both traditional yet stylish.

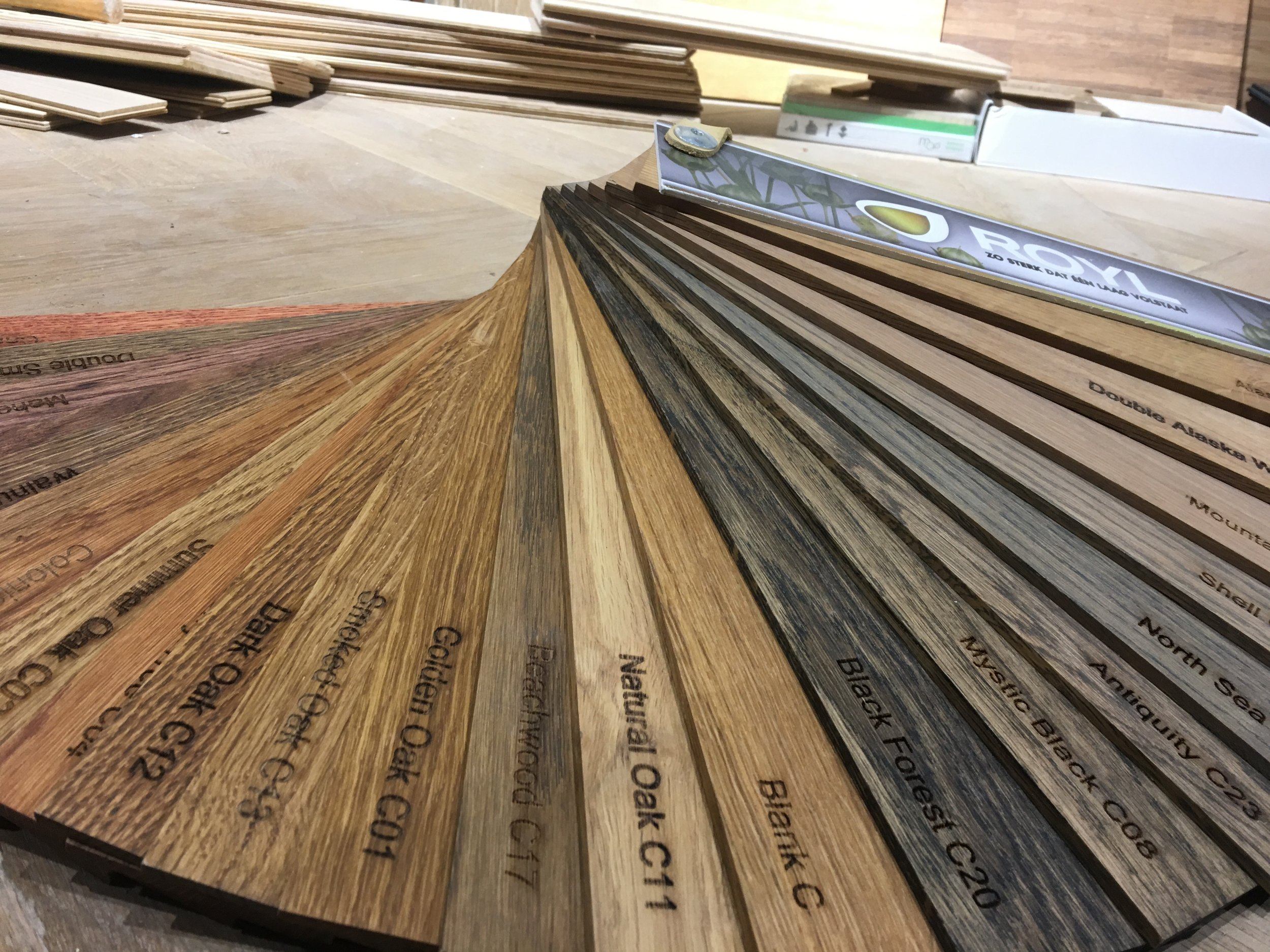

You can see how the colour can drastically effect the look of your chosen floor. On solid wood parquet flooring, you may sand the oil coat back to its raw natural wood and re-apply oil in another colour to refresh your floor (this can only be done so many times).

Different parquet floor aesthetics

What types of flooring can I choose from?

-Aged oak (or any type of wood) <nl Veroud eiken> :

If you like your floor with a little more of a rustic nature to it, aging the wood before installation is something you might be interested in. The wood is tumbled in a machine which softens any sharp ‘new looking’ edges, creates natural wear and tear signs and overall gives your floor its ‘been-here-a-while’ finish.

-Brushed oak (or any type of wood) <nl Geborsteld eiken> :

Parquet is often sanded smooth but another option you may choose from is to have your wood brushed before installation. This technique uses wire brushes to pull out the softer spring wood and exposing the harder summer wood in turn leaving your floor with a beautiful texture with the grain more prominent.

-Smoked oak (or any type of wood) <nl Gerookt eiken> :

If you want a slightly deeper, darker or smokier finish then smoking your wood is maybe something you might like to consider. You expose the wood to ammonia, the longer you leave it exposed, the more smoked it becomes and the ‘greyer’ the eventual finish. Smoked flooring is very popular at the minute in Amsterdam.

Solid wood or engineered wood when it comes to flooring?

Solid wood is used less and less in flooring today, mainly due to an increase in awareness of sustainability, reducing deforestation and changes in the market with people wanting bigger floorboards and an increase in underfloor heating etc…

Oak, one of the most common woods used for flooring, is a slow growing hardwood. Engineered wood flooring uses about 75% less of these slow growing trees. The backing of an engineered board is made from a multi-cross layer of faster growing hardwoods such as birch, eucalyptus and poplar. You can see how this is much better for the environment.

It is important to consider the type of adhesive used when comparing engineered wood flooring suppliers. The quality in which the structured wood pieces are glued plays a vital part in the life expectancy of your floor. These adhesives not only glue the multi layers of the plywood together but also the top layer of solid oak, maple or walnut or other exotic woods to the plywood base. There are not many manufacturers of high quality adhesives but hundreds of inferior copies where the longevity of the engineered floor boards may be in question.

We guarantee the engineered boards we source and install are made using only the best European adhesives that are environmentally friendly with no formaldehyde or other residues that could be harmful especially when underfloor heating is used.

What is Engineered Wood Flooring & Why Use it?

There is a huge range of styles and finishes when it comes to engineered wooden flooring. There are also many different structures and it is important to understand how the boards are manufactured to appreciate the effect they can have on the application you want to use the flooring for.

Finishes can range from antique hand distressed to tranquil smooth natural brushed boards all through to rustic and prime finishes and can all be used with underfloor heating. Engineered wood flooring is not to be confused with the cheap laminated versions.

Did you ever see a wooden floor that has totally warped and banana’d, all the pieces separated and just looking like one ugly mess? This will probably have been solid wood. Even a small leakage of water can cause solid flooring to totally misshape and this will never return to its natural shape.

Engineered wood however, with its multi-layer design (see image above) has only a top layer of solid upper wood flooring (therefore from the top you don’t notice the difference) and the underside is made up of built up layers of faster growing woods that are hardier and more versatile. The flooring itself won’t work so much throughout seasons and can cope with much more than solid when it comes to leaks and temperature changes.

The main concern people have when they come to choose between solid or engineered wood is of course it may seem you are only getting 3-6mm of solid wood as opposed to 2cm. When you come to sanding your floor, which you shouldn’t need to do for say - 10 years, you remove only 1mm est. from your flooring and the many times you come to sand your floor you can actually only sand down to the tongue anyway so this 1.5cm of solid wood (inclusive of the tongue section) is not wood you would use anyway.